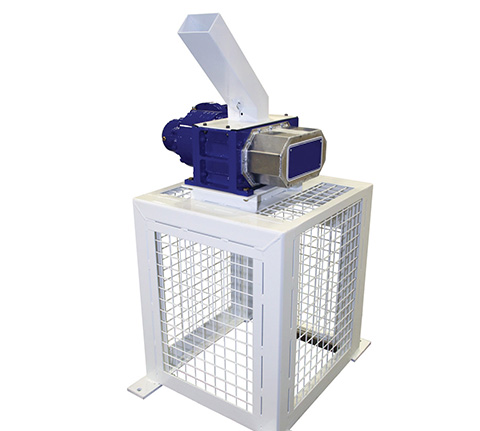

ST 5 Stationary Shredder

Shred-Tech® is here to help your business stay on top of one of the fastest growing segments in the shredding and recycling industry with our high-quality ST-5 Stationary Shredder. Only complete, physical destruction of data drives will ensure that the digital data is permanently destroyed, and this shredder machine is designed to effectively destroy data for your customers, rendering their information completely irretrievable. Able to absolutely destroy a data drive in five seconds or less, the shredder works with a light-duty throughput and can shred up to 750 hard drives per hour and up to 1,000 solid state drives per hour. Its high-quality and highly durable blades rip the devices into an optimal shred size with ease and efficiency. The hard drives have a max particle size of about 3.1” while solid-state drives have a max particle size of about 0.248” after one pass through the machine. Please note that this does not guarantee consistent shred size and is provided to give you an idea of how small the shredder can reduce a data drive into. This industrial shredder is electronically interlocked for safe and easy operation.

FEATURES

ApplicationsThe ST-5 Stationary Shredder can be used for the following applications:

E-Waste Recycling

Cell Phone Destruction

Hard Drive Destruction

Standard Features for the ST-5

The ST-5 Stationary Shredder is equipped with several highly reliable standard features that enhance its performance for optimized shredding power. Each component works with the rest of the system for flawless productivity and serviceability. These features include sharp and biting knives, durable hex shafts, and a user-friendly control panel, all of which are designed by our expert engineers to provide effective support for the rest of the shredding system. This gives the industrial shredder the strength to shred through hard drives for thorough data destruction.

Knives

The ST-5 Stationary Shredder is equipped with a series of sharp and heavy-duty knives that are more than capable of biting into thick data drives. Their sharp tips can pierce the material and rip the drive into shreds, effectively destroying all the information it contains. The ST-5 shredder machine features knives with diameters between 6 1/2" and 6 3/4" with a standard knife thickness between 1 5/8” and 3/8”

Hex Shafts

The machined hex shafts are uniquely designed to maximize knife placement options, opening up new areas of versatility and functionality that give you more control over the shredder. The design of the hex shafts also allows for easier knife removal and machine maintenance. Built several times stronger than a keyed shaft, the hex shaft drive system provides you with the highest knife-tip cutting force of any comparable shredder on the market.

Control Panel

The control panel for the ST-5 Stationary Shredder provides you with everything you need to take control over the entire shredding process. This system is incredibly easy to use and is designed by certified Shred-Tech® technicians for optimal useability. It features a number of benefits, including an hour meter, fused lockable disconnect, keyed power switch, illuminated function buttons, and a programmable logic controller for different shredder functions, including knife reversal on overload.

Optional Accessories for the ST-5

The ST-5 Stationary Shredder is designed to provide optimized shredder capabilities, and there are many optional accessories available to improve its overall performance. The shredder can be equipped with a hopper for easier loading, in-feed and out-feed conveyors for easier handling of materials, and a stand for lifted support. Each of these components are designed to complement the strength and capabilities of the shredder machine. For more information on even more optional accessories and how Shred-Tech® can improve your shredding solutions, just contact the Shred-Tech® team today, which is on standby 24/7!

Hopper

The hopper is a result of expert workmanship that Shred-Tech® is known for. It offers superior support that supports the loading process. Built with an emphasis on durability, the heavy-duty hopper is more than capable of handling day-to-day jobs with expert ease and efficiency while keeping up with the constant demands of the industry. The hopper can also be modified to suit the installation or application.

In-Feed & Out-Feed Conveyor

For an increase in efficiency, we offer in-feed and/or the out-feed conveyors. Both conveyors are designed to keep material flowing and the shredder working as efficiently as possible. The in-feed conveyor feeds the materials directly into the shredder while also keeping your workers away from the sharp blades. The out-feed conveyor then transfers the shredded remains of the products away from the shredder, preventing blockage or buildup, and sending them to a bin or other reservoir for collection and unloading.

Stand

With the help of a solid and reliable stand, you can provide effective support to the entire shredder machine and lift it off the ground to provide clearance in your facility space for the use of additional equipment. This stand is strong enough to support the entire weight of the shredder with ease. While keeping the shredder off the ground, shredded material then can drop down into a container or onto any downstream equipment, such as a conveyor.

ST-5-STATIONARY-SHREDDER TECHNICAL SPECIFICATIONS

| PRODUCT SPECIFICATIONS | |

|---|---|

| Throughput Up To (Hard Drives/hr) | 750 |

| Throughput Up To (Solid State Drives/hr) | 1000 |

| Throughput | <1 t/hr |

| Size of Material (LxW): | 127 x 304.8 mm. |

| Shred Size/Fraction Size: | Strips (Inconsistent) |

| Security Level (Hard Drives/Solid State Drives): | H-4 / E-3 |

| Particle Size (Hard Drives/Solid State Drives): | Max 78.74 mm Squared / Max 6.2992mm Squared |

| M/C Length | 1,607 mm. |

| M/C Width | 914 mm. |

| M/C Height | 1,524 mm. |

| M/C Weight | 408 kg. |

| Floor Space | 0.97 sq.m. |

| Drive | Electric |

| Number of motor | 1 |

| Shredder Power | 3.7 kw. |

| Voltage | 208-600 |

| Hertz | 50/60 |

| Knife Thickness (STD) | 42 mm. |

| Knife Diameter | 165.1 / 171.45 mm. |

| Hex Size | 60 mm. |

| Distance Between Shafts | 152 mm. |

| Cutting Chamber | 127x318 / 76.2 x 318 mm. |

| Discharge Height | 762 mm. |

| Hopper Height | 381 mm. |

| Hopper Opening | 32x127 mm. |

| Stand Opening (Width) | 533 mm. |

| Stand Opening (Length) | 597 mm. |

| Aapplication | E-Waste, Hard Drives, Phones |

| PRODUCT SPECIFICATIONS | |

|---|---|

| Throughput Up To (Hard Drives/hr) | 750 |

| Throughput Up To (Solid State Drives/hr) | 1000 |

| Throughput | <1 t/hr |

| Size of Material (LxW): | 5" x 12" inch |

| Shred Size/Fraction Size: | Strips (Inconsistent) |

| Security Level (Hard Drives/Solid State Drives): | H-4 / E-3 |

| Particle Size (Hard Drives/Solid State Drives): | Max 3.1" Squared / Max 0.248" Squared |

| M/C Length | 42" |

| M/C Width | 36" |

| M/C Height | 60" |

| M/C Weight | 900 lbs |

| Floor Space | 10 1/2 sq.ft. |

| Drive | Electric |

| Power | 5 HP |

| Voltage | 208-600 |

| Hertz | 50/60 |

| Knife Thickness (STD) | 1 5/8" |

| Knife Diameter | 6 1/2" / 6 3/4" |

| Hex Size | 2 3/8" |

| Distance Between Shafts | 6" |

| Cutting Chamber | 5"x12 1/2" / 3"x12 1/2" |

| Discharge Height | 30" |

| Hopper Height | 15" |

| Hopper Opening | 1 1/4" x 5" |

| Number of Motors | 1 |

| Stand Opening (Width) | 21" |

| Stand Opening (Length) | 23 1/2" |

| Aapplication | E-Waste, Hard Drives, Phones |

| Model/Spec | M/C Length x Width x Height (mm.) |

M/C Weight (kg) |

Floor Space (sq.m.) |

Drive | Power (kw) |

Voltage | Hertz | Knife Thickness (STD) (mm.) | Hex Size (mm.) |

Distance Between Shafts(mm.) | Cutting Chamber (mm.) | Discharge Height (mm.) | Hopper Height (mm.) | Hopper Opening (mm.) | Stand Opening Width (mm.) |

Stand Opening Length (mm.) | Number of Motors | Number of Knives | Knife Diameter (mm.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ST-5 Stationary Shredder | 1,607 x 914 x 1,524 | 408 | 0.97 | Electric | 3.7 | 208-600 | 50/60 | 42 | 60 | 152 | 127x318 / 76.2 x 318 | 762 | 381 | 32x127 | 533 | 597 | 1 | - | 165.1 / 171.45 |

| ST-15E | 1,473 x 1,016 x 2,286 | 612 | 1.50 | Electric | 7.35-22 | 208-600 | 50/60 | 6.35, 9.5, 15.8, 30 | 68 | 149 | 533 x 330 | 1,016 | 965 | 599 x 711 | 762 | 965 | 1 | 73, 50, 30, 14 | 171 |

| ST-25ES | 1,727 x 686 x 1,981 | 907 | 1.20 | Electric | 11-18 | 208-600 | 50/60 | 10 16 22 30 | 68 | 149 | 699 x 406 | 1,016 | 508 | - | 533 | 762 | 1 | 72, 40, 32, 24 | 197 |

| ST-25E | 2,083 x 686 x 1,981 | 1,043 | 1.50 | Electric | 11-18 | 208-600 | 50/60 | 10 16 22 30 | 68 | 149 | 699 x 406 | 1,016 | 508 | - | 533 | 1,118 | 1 | 72 40 32 24 | 197 |

| ST-25EL | 2,261 x 685 x 1,981 | 1,134 | 1.60 | Electric | 11-18 | 208-600 | 50/60 | 10 16 22 30 | 68 | 149 | 699 x 406 | 1,016 | 508 | - | 533 | 1,295 | 1 | 72, 40, 32, 24 | 197 |

| ST-35 | 2,083 x 1,626 x 2,667 | 1,279 | 3.40 | Electric | 22 - 40 | 208-600 | 50/60 | 16 13 | 102 | 203 | 635 x 533 | 1,016 | 1,118 | 533 | 533 | 1,016 | 2 | 46 52 | 241 |

| ST-50E | 2,794 x 1,143 x 2,718 | 2,359 | 3.10 | Electric | 30-37 | 208-600 | 50/60 | 16 22 30 41 | 86 | 191 | 1,016 x 533 | 1,016 | 1,118 | 1,016 x 1,016 | 533 | 1,905 | 1 or 2 | 64, 48, 32, 24 | 254 |

| ST-50EL | 3,048 x 1,143 x 2,718 | 2,359 | 3.50 | Electric | 30-37 | 208-600 | 50/60 | 16 22 30 41 | 86 | 191 | 1,270 x 533 | 1,016 | 1,118 | 1,270 x 1,016 | 533 | 1,905 | 1 or 2 | 64, 48, 32, 24 | 254 |

| ST-75L | 3,722 x 1,295 x 2,667 | 4,173 | 4.80 | Electric | 45-75 | 208-600 | 50/60 | 16, 22, 25, 38, 51 | 110 | 240 | 1,590 x 635 | 1,067 | 864 | 1,575 x 1,168 | 635 | 2,235 | 1 or 2 | 90 60 40 | 318 |

| ST-75E | 3,404 x 1,295 x 2,667 | 3,810 | 4.40 | Electric | 45-75 | 208-600 | 50/60 | 16, 22, 25, 38, 51 | 110 | 240 | 1,273 x 635 | 1,067 | 864 | 1,270 x 1,168 | 635 | 1,930 | 1 or 2 | 72 48 32 | 318 |

| ST-75H | 2,545 x 1,295 x 2,667 | 3,130 | 3.30 | Hydraulic | 56 | 208-600 | 50/60 | 16, 22, 25, 38, 51 | 110 | 240 | 1273 x 635 | 1,067 | 864 | 1,270 x 1,168 | 635 | 1,930 | 1 or 2 | 72 48 32 | 318 |

| ST-75ES | 3,073 x 1,295 x 2,667 | 3,447 | 4.00 | Electric | 45-75 | 208-600 | 50/60 | 16, 22, 25, 38, 51 | 110 | 240 | 956 x 635 | 1,067 | 864 | 965 x 1,168 | 25 | 1,626 | 1 or 2 | 54 36 24 | 318 |

| ST-75HS | 2,184 x 1,295 x 2,667 | 2,767 | 2.90 | Hydraulic | 56 | 208-600 | 50/60 | 16, 22, 25, 38, 51 | 110 | 240 | 956 x 635 | 1,067 | 864 | 965 x 1,168 | 635 | 1,626 | 1 or 2 | 54 36 24 | 318 |

| ST-100E | 3,683 x 1,397 x 2,794 | 6,577 | 5.10 | Electric | 45-112 | 208-600 | 50/60 | 38 48 64 | 137 | 308 | 1,537 x 813 | 1,092 | 940 | 1,524 x 1,372 | 838 | 2,362 | 1 or 2 | 40 32 24 | 413 |

| ST-100H | 2,921 x 1,397 x 2,794 | 5,488 | 4.00 | Hydraulic | 75-112 | 208-600 | 50/60 | 38 48 64 | 137 | 308 | 1,537 x 813 | 1,092 | 940 | 1,524 x 1,372 | 838 | 2,362 | 1 or 2 | 40 32 24 | 413 |

| ST-100ES | 3,302 x 1,397 x 2,794 | 5,534 | 4.60 | Electric | 45-112 | 208-600 | 50/60 | 38 48 64 | 137 | 308 | 1,143 x 813 | 1,092 | 940 | 1,524 x 1,372 | 838 | 1,981 | 1 or 2 | 30 24 18 | 413 |

| ST-100HS | 2,540 x 1,397 x 2,794 | 4,672 | 3.50 | Hydraulic | 75-112 | 208-600 | 50/60 | 38 48 64 | 137 | 308 | 1,143 x 813 | 1,092 | 940 | 1,524 x 1,372 | 838 | 1,981 | 1 or 2 | 30 24 18 | 413 |

| ST-300ES | 3,912 x 1,651 x 711 | 8,618 | 6.50 | Electric | 75-149 | 208-600 | 50/60 | 41, 48, 59, 73 | 168 | 381 | 1651 x 1016 | 1,219 | 1,270 | - | 1,295 | 2,743 | 2 | 43, 34, 27, 22 | 508 |

| ST-300E | 3,912 x 1,651 x 711 | 9,525 | 6.90 | Electric | 75-149 | 208-600 | 50/60 | 41, 48, 59, 73 | 168 | 381 | 1651 x 1016 | 1,219 | 1,270 | - | 1,295 | 3,048 | 2 | 43, 34, 27, 22 | 508 |

| ST-300EL | 3,912 x 1,651 x 711 | 10,433 | 7.30 | Electric | 75-149 | 208-600 | 50/60 | 41, 48, 59, 73 | 168 | 381 | 1651 x 1016 | 1,219 | 1,270 | - | 1,295 | 3,302 | 2 | 43, 34, 27, 22 | 508 |

| ST-400ES | 4,357 x 1,956 x 4,064 | 13,608 | 8.40 | Electric | 441-883 | 208-600 | 50/60 | 38 48 73 76 | 177 or 203 | 432 | 1,346 x 1,168 | 2,032 | 1,016 | - | 1,194 | 2,161 | 2 | 35 28 22 18 | 578 |

| ST-400E | 4,662 x 1,956 x 4,064 | 14,969 | 8.90 | Electric | 441-883 | 208-600 | 50/60 | 38 48 73 76 | 177 or 203 | 432 | 1,651 x 1,168 | 2,032 | 1,016 | - | 1,194 | 2,997 | 2 | 43 34 27 22 | 578 |

| ST-400EL | 4,931 x 1,956 x 4,064 | 15,876 | 9.30 | Electric | 441-883 | 208-600 | 50/60 | 38 48 73 76 | 177 or 203 | 432 | 1,905 x 1,168 | 2,032 | 1,016 | - | 1,194 | 3,531 | 2 | 50 40 31 26 | 578 |

| ST-400EXL | 5,222 x 1,956 x 4,064 | 17,236 | 9.80 | Electric | 441-883 | 208-600 | 50/60 | 38 48 73 76 | 177 or 203 | 432 | 2,210 x 1,168 | 2,032 | 1,016 | - | 1,194 | 3,835 | 2 | 57 46 36 30 | 578 |

| ST-1200HS | 4,356 x 2,530 x 4,388 | 32,037 | 11.10 | Hydraulic | 447-895 | - | - | 74.6 | 276 | 606 | 1,575 x 1,778 | 2,070 | 1,487 | 2,089 x 1,799 | 2,692 | 2,362 | 2 | 24 | 806 |

| ST-1200H | 4,940 x 2,530 x 4,388 | 35,380 | 12.50 | Hydraulic | 447-895 | - | - | 74.6 | 276 | 606 | 1,575 x 2,369 | 2,070 | 1,487 | 2,089 x 2,388 | 3,277 | 2,362 | 2 | 32 | 806 |

| ST-1200HL | 5,531 x 2,530 x 4,388 | 38,737 | 14.00 | Hydraulic | 447-895 | - | - | 74.6 | 276 | 606 | 1,575 x 2,959 | 2,070 | 1,487 | 2,089 x 2,978 | 3,861 | 2,362 | 2 | 40 | 806 |

| ST-15ES | 1,372 x 1,016 x 2,286 | 567 | 1.40 | Electric | 7.35-22 | 208-600 | 50/60 | 6.35, 9.5, 15.8, 30 | 68 | 149 | 432 x 330 | 1,016 | 965 | 559 x 610 | 762 | 864 | 1 | 73, 50, 30, 14 | 171 |

| ST-50ES | 2,540 x 1,143 x 2,718 | 2,223 | 2.78 | Electric | 15-37 | 208-600 | 50/60 | 16 22 30 41 | 86 | 191 | 533 x 762 | 1,016 | 1,118 | 762 x 1,016 | 533 | 1,397 | 1 or 2 | 64, 48, 32, 24 | 254 |

| ST-5 Portable Shredder | - x - x - | 408 | 0.98 | Electric | 2.2 | 208-240 | 50/60 | 41.3 / 9.5 | 60.3 | 152.4 | 127 x 317.5 / 76.2 x 317.5 | - | 381 | - | - | - | 1 | - | 165.1 / 171.45 |

| ST-8 Stationary Shredder | - x - x - | - | - | Electric | 11 | - | - | - | 84.8 | 190.5 | 401.6 x 101.6 / 401.6 x 139.7 | 330 | 1,270 | - | - | - | 1 | 5 / 14 | 203.2 / 203.2 |

| Model/Spec | M/C Length x Width x Height (") |

M/C Weight (lbs) |

Floor Space (sq.ft.) |

Drive | Power (HP) |

Voltage | Hertz | Knife Thickness (STD) (") | Hex Size (") |

Distance Between Shafts(") | Cutting Chamber (") | Discharge Height (") | Hopper Height (") | Hopper Opening (") | Stand Opening Width (") | Stand Opening Length (") | Number of Motors | Number of Knives | Knife Diameter (") |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ST-5 Stationary Shredder | 42" x 36" x 60" | 900 | 10 1/2 | Electric | 5 | 208-600 | 50/60 | 1 5/8" | 2 3/8" | 6" | 5"x12 1/2" / 3"x12 1/2" | 30" | 15" | 1 1/4" x 5" | 21" | 23 1/2" | 1 | - | 6 1/2" / 6 3/4" |

| ST-15E | 58 " x 40 " x 90" | 1,350 | 16 | Electric | 10-30 | 208-600 | 50/60 | 1/4", 3/8", 5/8", 1 3/16" | 2 11/16" | 5 7/8" | 21" x 13" | 40" | 38" | 22" x 28" | 30" | 38" | 1 | 73, 50, 30, 14 | 6 3/4" |

| ST-25ES | 68 " x 27 " x 78" | 2,000 | 13 | Electric | 15-25 | 208-600 | 50/60 | 3/8" 5/8" 7/8" 1 3/16" | 2 11/16" | 5 7/8" | 27 1/2" x 16" | 40" | 20" | - | 21" | 30" | 1 | 72, 40, 32, 24 | 7 3/4" |

| ST-25E | 82 " x 27 " x 78" | 2,300 | 16 | Electric | 15-25 | 208-600 | 50/60 | 3/8" 5/8" 7/8" 1 3/16" | 2 11/16" | 5 7/8" | 27 1/2" x 16" | 40" | 20" | - | 21" | 44" | 1 | 72 40 32 24 | 7 3/4" |

| ST-25EL | 89 " x 27 " x 78" | 2,500 | 17 | Electric | 15-25 | 208-600 | 50/60 | 3/8" 5/8" 7/8" 1 3/16" | 2 11/16" | 5 7/8" | 27 1/2" x 16" | 40" | 20" | - | 21" | 51" | 1 | 72, 40, 32, 24 | 7 3/4" |

| ST-35 | 82 " x 64 " x 105" | 2,820 | 37 | Electric | 30 - 55 | 208-600 | 50/60 | 5/8" 1/2" | 4" | 8" | 25" x 21" | 40" | 44" | 21" | 21" | 40" | 2 | 46 52 | 9 1/2" |

| ST-50E | 110 " x 45 " x 107" | 5,200 | 34 | Electric | 40-45 | 208-600 | 50/60 | 5/8", 7/8", 1 3/16", 1 5/8" | 3 3/8" | 7 1/2" | 40" x 21" | 40" | 44" | 40" x 40" | 21" | 75" | 1 or 2 | 64, 48, 32, 24 | 10" |

| ST-50EL | 120 " x 45 " x 107" | 5,500 | 38 | Electric | 40-50 | 208-600 | 50/60 | 5/8", 7/8", 1 3/16", 1 5/8" | 3 3/8" | 7 1/2" | 50" x 21" | 40" | 44" | 50" x 40" | 21" | 75" | 1 or 2 | 64, 48, 32, 24 | 10" |

| ST-75L | 147 " x 51 " x 105" | 9,200 | 52 | Electric | 60-100 | 208-600 | 50/60 | 5/8", 7/8", 1", 1 1/2", 2" | 4 5/16" | 9 7/16" | 25" x 62 5/8" | 42" | 34" | 62" x 46" | 25" | 88" | 1 or 2 | 90 60 40 | 12 1/2" |

| ST-75E | 134 " x 51 " x 105" | 8,400 | 48 | Electric | 60-100 | 208-600 | 50/60 | 5/8", 7/8", 1", 1 1/2", 2" | 4 5/16" | 9 7/16" | 50 1/8" x 25" | 42" | 34" | 50" x 46" | 25" | 76" | 1 or 2 | 72 48 32 | 12 1/2" |

| ST-75H | 99 " x 51 " x 105" | 6,900 | 35 | Hydraulic | 75 | 208-600 | 50/60 | 5/8", 7/8", 1", 1 1/2", 2" | 4 5/16" | 9 7/16" | 50 1/8" x 25" | 42" | 34" | 50" x 46" | 25" | 76" | 1 or 2 | 72 48 32 | 12 1/2" |

| ST-75ES | 121 " x 51 " x 105" | 7,600 | 43 | Electric | 60-100 | 208-600 | 50/60 | 5/8", 7/8", 1", 1 1/2", 2" | 4 5/16" | 9 7/16" | 37 5/8" x 25" | 42" | 34" | 38" x 46" | 635" | 64" | 1 or 2 | 54 36 24 | 12 1/2" |

| ST-75HS | 86 " x 51 " x 105" | 6,100 | 31 | Hydraulic | 75 | 208-600 | 50/60 | 5/8", 7/8", 1", 1 1/2", 2" | 4 5/16" | 9 7/16" | 37 5/8" x 25" | 42" | 34" | 38" x 46" | 25" | 64" | 1 or 2 | 54 36 24 | 12 1/2" |

| ST-100E | 145 " x 55 " x 110" | 14,500 | 55 | Electric | 60-150 | 208-600 | 50/60 | 1 1/2" 1 7/8" 2 1/2" | 5 3/8" | 12 1/8" | 60 1/2" x 32" | 43" | 37" | 60" x 54" | 33" | 93" | 1 or 2 | 40 32 24 | 16 1/4" |

| ST-100H | 115 " x 55 " x 110" | 12,100 | 44 | Hydraulic | 100-150 | 208-600 | 50/60 | 1 1/2" 1 7/8" 2 1/2" | 5 3/8" | 12 1/8" | 60 1/2" x 32" | 43" | 37" | 60" x 54" | 33" | 93" | 1 or 2 | 40 32 24 | 16 1/4" |

| ST-100ES | 130 " x 55 " x 110" | 12,200 | 50 | Electric | 60-150 | 208-600 | 50/60 | 1 1/2" 1 7/8" 2 1/2" | 5 3/8" | 12 1/8" | 45" x 32" | 43" | 37" | 60" x 54" | 33" | 78" | 1 or 2 | 30 24 18 | 16 1/4" |

| ST-100HS | 100 " x 55 " x 110" | 10,300 | 38 | Hydraulic | 100-150 | 208-600 | 50/60 | 1 1/2" 1 7/8" 2 1/2" | 5 3/8" | 12 1/8" | 45" x 32" | 43" | 37" | 60" x 54" | 33" | 78" | 1 or 2 | 30 24 18 | 16 1/4" |

| ST-300ES | 154 " x 65 " x 28" | 19,000 | 70 | Electric | 100-200 | 208-600 | 50/60 | 1 5/8", 1 7/8", 2 1/3", 2 7/8" | 6 5/8" | 15" | 65" x 40" | 48" | 50" | - | 51" | 108" | 2 | 43, 34, 27, 22 | 20" |

| ST-300E | 166 " x 65 " x 28" | 21,000 | 75 | Electric | 100-200 | 208-600 | 50/60 | 1 5/8", 1 7/8", 2 1/3", 2 7/8" | 6 5/8" | 15" | 65" x 40" | 48" | 50" | - | 51" | 120" | 2 | 43, 34, 27, 22 | 20" |

| ST-300EL | 176 " x 65 " x 28" | 23,000 | 79 | Electric | 100-200 | 208-600 | 50/60 | 1 5/8", 1 7/8", 2 1/3", 2 7/8" | 6 5/8" | 15" | 65" x 40" | 48" | 50" | - | 51" | 130" | 2 | 43, 34, 27, 22 | 20" |

| ST-400ES | 168 " x 77 " x 160" | 30,000 | 90 | Electric | 600-1200 | 208-600 | 50/60 | 1 1/2" 1 7/8" 2 1/2" 3" | 7" or 8" | 17" | 53" x 46" | 80" | 40" | - | 47" | 103" | 2 | 35 28 22 18 | 22 3/4" |

| ST-400E | 180 " x 77 " x 160" | 33,000 | 96 | Electric | 600-1200 | 208-600 | 50/60 | 1 1/2" 1 7/8" 2 1/2" 3" | 7" or 8" | 17" | 65" x 46" | 80" | 40" | - | 47" | 118" | 2 | 43 34 27 22 | 22 3/4" |

| ST-400EL | 190 " x 77 " x 160" | 35,000 | 100 | Electric | 600-1200 | 208-600 | 50/60 | 1 1/2" 1 7/8" 2 1/2" 3" | 7" or 8" | 17" | 75" x 46" | 80" | 40" | - | 47" | 139" | 2 | 50 40 31 26 | 22 3/4" |

| ST-400EXL | 200 " x 77 " x 160" | 38,000 | 106 | Electric | 600-1200 | 208-600 | 50/60 | 1 1/2" 1 7/8" 2 1/2" 3" | 7" or 8" | 17" | 87" x 46" | 80" | 40" | - | 47" | 151" | 2 | 57 46 36 30 | 22 3/4" |

| ST-15ES | 54 " x 40 " x 90" | 1,250 | 15.5 | Electric | 10-30 | 208-600 | 50/60 | 1/4", 3/8", 5/8", 1 3/16" | 2 11/16" | 5 7/8" | 17" x 13" | 40" | 38" | 22" x 24" | 30" | 34" | 1 | 73, 50, 30, 14 | 6 3/4" |

| ST-50ES | 100 " x 45 " x 107" | 4,900 | 30 | Electric | 40-50 | 208-600 | 50/60 | 5/8", 7/8", 1 3/16", 1 5/8" | 3 3/8" | 7 1/2" | 21" x 30" | 40" | 44" | 30" x 40" | 21" | 55" | 1 or 2 | 64, 48, 32, 24 | 10" |

| ST-5 Portable Shredder | - x - x - | 900 | 10 1/2" | Electric | 3 | 208-240 | 50/60 | 1 5/8" / 3/8" | 2 3/8" | 6" | 5" x 12 1/2" / 3" x 12 1/2" | - | 43 1/2" | - | - | - | 1 | - | 6 1/2" / 6 3/4" |

| Download ST 5 Stationary Shredder Sheet |

|---|

data-big="" data-title="" data-description="" >

data-big="" data-title="" data-description="" >